CNC Drag Engraver – Magnetically Retained

About

When drag engraving our spindle squares there was an operator error moving the diamond off the edge of the stock and back over again. This caused the diamond to break free from the tool and of course this was also the last bit. The bits were $25 and required the entire tool to be disassembled. You had to custom order. The wait time would be another 2 weeks and this wasn’t acceptable. You couldn’t run down to your ace warehouse and pick up what you needed. There had to be a better way that was more economical, easier, available and worked on our smaller machines that didn’t the ability to use large collets.

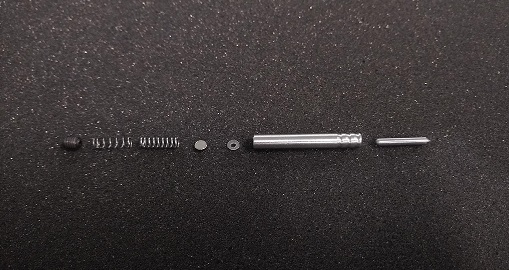

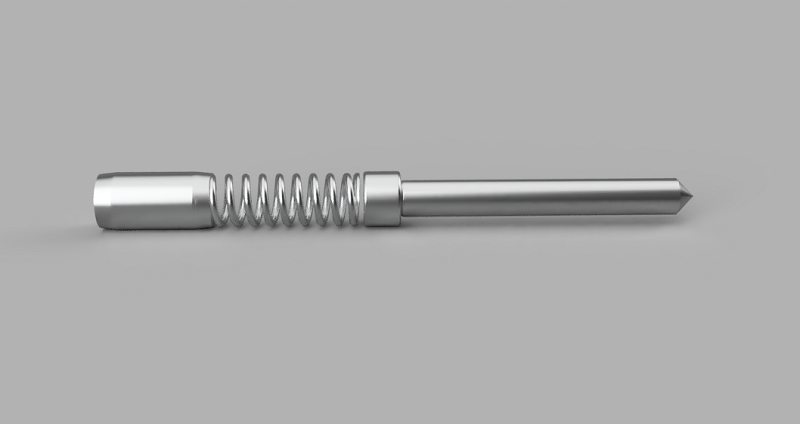

Specifications

- Uses 1/8 x 1″ carbide or diamond tools, dremel: #9924 (included 60 Degree Carbide 1/8 x 1″, brazed carbide on steel shank)

- Dimensions: 1/4″ x 1.625″

- Materials:

- Body – 303 Stainless Steel

- Bushing – Natural Nylon

- Spring (4.2lbs) – 302 Stainless Steel

- Spring Pin – 420 Stainless Steel

- Magnet – N52 Chrome Plated

- Lubrication: Dynatex 49550 Industrial Aluminum Anti-Seize and Lubricating Compound

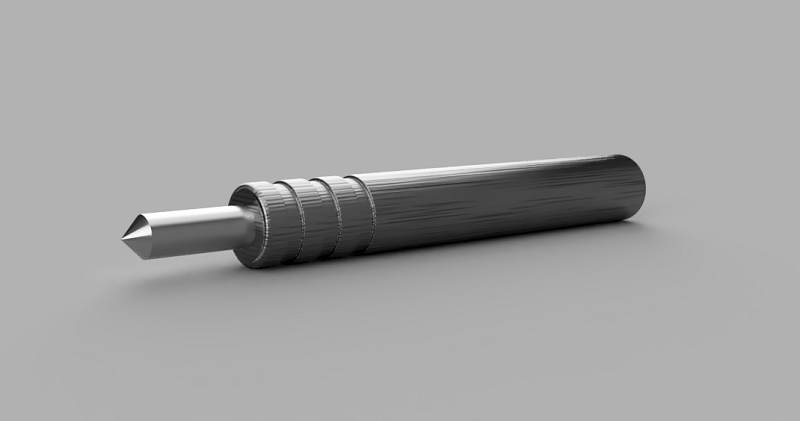

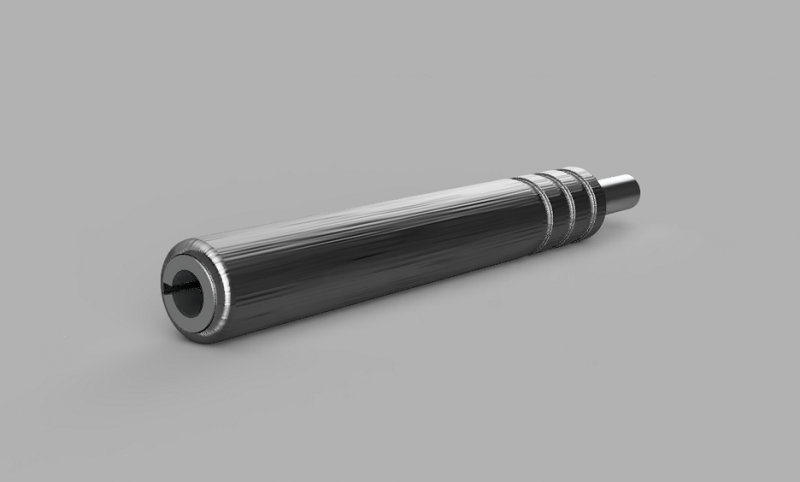

Adjustable Drag Engraver

In order to allow for finer detailed engraver we designed one that allows for adjustment and the hot-swapping of springs. This allow the drag engraver to do very detailed work on items such as pcb boards or fine in engravings in soft materials.

Differences with Adjustable Drag Engraver:

- Includes 2 Springs: 1.3lbs and 4.2lbs, user can also use their own.

- Adjustment screw has 1/2″ of travel in body.

- 12/24 Alloy Adjustment Set Screw instead of roll pin (3/32″ allen key).

Bits

We have had the best results utilizing the carbide bits with softer materials and metals such as brass, copper, mild steel, aluminum, acrylics and other plastics. The diamond bits can do everything the carbide does plus hardened steel, granite, glass and other tough materials.

Instructions

- Turn off your machine before loading tool

- Load Drag Engraver into collet (designed for collets, only adjustable engraver can be used in endmill holder or shrink fit tooling). Tighten to 10-15 inch-pounds.

- Insert engraving bit. It should slide in freely.

- Turn on machine and keep the spindle off (the spindle should be off for this tool).

- Set the tool into the work piece and drop the engraver .005 to .020″ depending on depth of engraving desired.

- Engage or use machine with a retract of .125″ clearance height.

- Use the engraving bit from here as you would another tool.

Instructions for CAM

In Use

How do I get solder mask with my @bantamtools? After I did several months of testing, Boring Research now has a very low cost *adjustable* engraver available: https://t.co/FmCKQuDOXg

(I have no financial ties to Bantam or Boring Research. I just like seeing cool things happen.) pic.twitter.com/Hg4QQhKV7U

— _MG_ (@_MG_) October 3, 2019

Order

Drag Engravers and Bits are out of stock.

Drag Engraver $30

Adjustable Drag Engraver $40

Extra Carbide Bit $4

Diamond Bit $8